Application

Differential Scanning Calorimetry (DSC) is a widely recognized thermal analysis technique specifically tailored for the thermal characterization of polymers and polymer blends, including:

- Thermoplastics (polymers, moulding compounds, and other moulding materials--with or without fillers, fibres, or reinforcements)

- Thermosets (uncured or cured materials--with or without fillers, fibres, or reinforcements)

- Elastomers (with or without fillers, fibres, or reinforcements)

DSC is engineered for the observation and quantitative measurement of various intrinsic properties and associated thermal phenomena of the aforementioned materials, such as:

- Physical transitions (e.g., glass transition; phase transitions including melting, crystallization, and polymorphic transitions)

- Chemical reactions (e.g., polymerization, crosslinking, and curing of elastomers and thermosets)

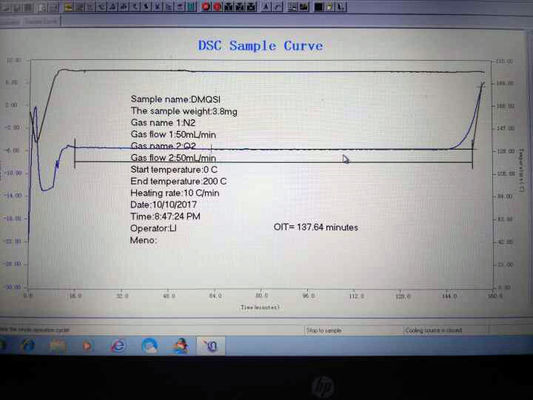

- Oxidative stability

- Heat capacity

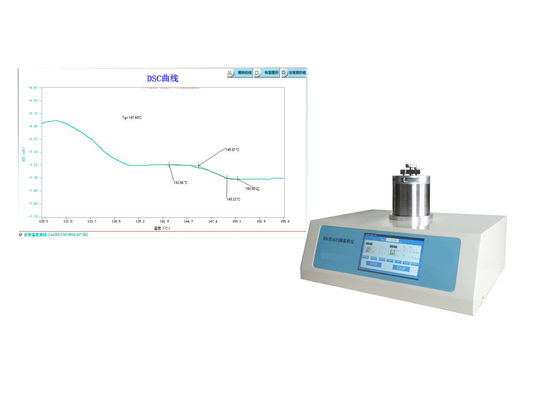

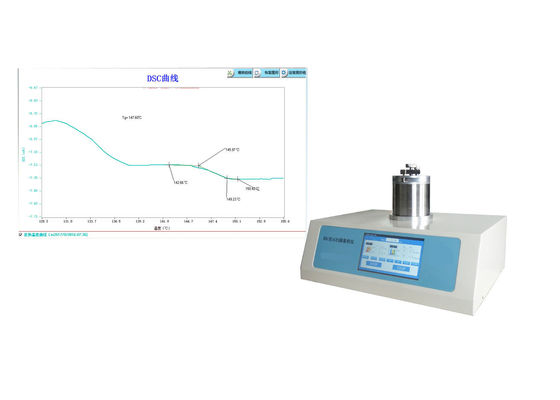

Instrument Features

1. Display System

Equipped with an LCD liquid crystal display with blue backlight, it presents abundant real-time information--including set temperature, sample temperature, oxygen flow rate, nitrogen flow rate, differential thermal signal, and the status of various switches--enabling comprehensive monitoring of test parameters.

2. Communication Interface

The USB communication interface offers strong universality, stable and uninterrupted data transmission, and supports an automatic reconnection function--ensuring reliable connectivity during long-duration testing processes.

3. Furnace Structure & Heating Performance

- The furnace body features a compact design with a stepless adjustable heating rate, flexibly adapting to diverse temperature-rise requirements for different test scenarios.

- The installation process is optimized with a full mechanical fixing method, which completely eliminates the risk of differential thermal signal contamination by colloids inside the furnace--effectively safeguarding test data accuracy.

4. Dual Temperature Probe Design

This design ensures high repeatability of sample temperature measurement, addressing the limitations of single-probe systems:

- A temperature probe mounted on the furnace wall implements PID control of the overall furnace temperature. However, thermal inertia causes a certain deviation between the furnace wall temperature and the actual sample temperature, and this deviation varies with seasons.

- To resolve this issue, an additional temperature probe is installed at the bottom of the sample to measure its real-time actual temperature. Combined with our proprietary temperature control technology, the furnace wall temperature is precisely regulated to make the sample temperature reach the set value--significantly reducing errors in both differential thermal signals and temperature data.

5. Gas Atmosphere Control

A digital gas mass flow meter enables automatic switching between two gas atmosphere flows. It features fast switching speed and short stabilization time--maintaining consistent and reliable atmosphere conditions throughout the test cycle.

6. Calibration & Cooling Functions

- Standard samples are provided to facilitate customers' calibration of temperature coefficients, simplifying routine verification operations.

- A dedicated furnace cooling interface is integrated to support rapid furnace cooling, shortening the interval between consecutive tests and improving work efficiency.

7. Software Capabilities

The software adapts to computer screens of various resolutions, automatically adjusting the curve display mode according to the screen size. It is compatible with both laptops and desktops, and supports operating systems such as Win2000, XP, VISTA, and WIN7.

It supports user-programmable test protocols to realize automated testing workflows. The software offers dozens of built-in instructions, allowing users to flexibly combine and save instructions based on their specific test procedures--simplifying complex operations into one-key execution.

Frequently Asked Questions

Q1: What is a Differential Scanning Calorimeter (DSC)?

A1: A Differential Scanning Calorimeter (DSC) is a high-precision thermal analysis instrument that measures the heat flow difference between a sample and a reference material under programmable temperature conditions. It is widely utilized to characterize the thermal properties and associated thermal phenomena of various materials.

Q2: What is the main purpose of a DSC machine?

A2: Its primary objective is the quantitative analysis of materials' thermal behaviors, including physical transitions (glass transition, melting, crystallization, polymorphic transitions), chemical reactions (polymerization, crosslinking, curing), oxidative stability, and heat capacity. It delivers actionable data to support material R&D, quality control, and compliance verification processes.

Q3: Which materials can a DSC machine test?

A3: It is applicable to a diverse spectrum of materials, including but not limited to polymers (thermoplastics, thermosets, elastomers) with or without fillers, fibers, or reinforcements, pharmaceuticals, food products, cosmetics, inorganic materials, metals, and composite materials.

Q4: What are the key technical parameters of a DSC machine?

A4: Typical key technical parameters include:

- Temperature range: Ambient to 500°C (up to 1000°C for high-temperature models)

- Temperature control accuracy: ±0.1°C to ±0.5°C

- Heating/cooling rates: 0.1-100°C/min (stepless adjustable)

- Atmosphere control: Supports inert gases (N₂, Ar) or oxidative gas (O₂), equipped with digital gas mass flow meters for precise flow regulation

Q5: Which standards does a DSC machine comply with?

A5: It strictly complies with international, regional, and national standards, such as ISO 11357 (Polymer thermal analysis), ASTM E967 (Standard test method for DSC), and GB/T 19466 (Plastic--Differential scanning calorimetry (DSC) testing), ensuring the traceability and compliance of test results.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!